Emission Master Tanks

Emission Master Tanks

Emission Master software calculates air emissions from fixed roof and floating roof storage tank operations on daily, monthly, quarterly, or annual basis and supports the calculation of fugitive emissions.

Supported Storage Tank Models

| Fixed Roof | Floating Roof |

|---|---|

| Vertical Cone Roof | External Floating Roof |

| Vertical Dome Roof | Domed External Floating Roof |

| Horizontal Style | Internal Floating Roof |

| Underground or Isothermal | Roof Landings |

| Tank Cleaning (coming soon) |

Fixed & Floating Roof Storage Tank Revisions

Emission Master Tanks calculations are based on the latest EPA Chapter 7.1 calculations. EPA Tanks software is no longer supported by the EPA. Version 8.4.3, released January 17, 2020 includes the following key features:

∙ Expansion of tank colors, reflective conditions, and climate data.

∙ Tank insulation is now a factor in working & breathing losses.

∙ Substantial revision of vapor space volume for horizontal tanks.

∙ We enhanced the detail calculation report for spot check validation.

∙ Emissions can be calculated for monthly or annual periods.

Compatibility with EPA Tanks Software

Tanks, Climate, Fittings, Seals, and Deck Seams can be imported into Emission Master directly from EPA Tanks 4 databases. Chemical and Mixture data can also be imported from EPA Tanks databases for a one-time service charge. We support a smooth transition from EPA Tanks to Emission Master and have extensive experience migrating data from many different data sources. Please ask about our data migration capabilities if you would like to import data from other programs, spreadsheets or databases.

Key Features

- Can be configured to calculate using 2006 or 2019 AP-42 EPA equations.

- Contains most recent climate data from 2019 AP-42 Chapter 7.1.

- Storage tank operating periods can be specified for daily, monthly, quarterly, or yearly.

- An easy to use interface if provided for entering storage tank calculations manually.

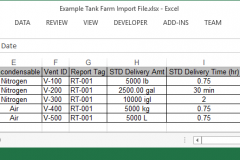

- Calculations for many storage tanks may be entered directly from Excel.

- Emissions are speciated based on the storage tank mixture contents as well has grouped by classification (VOC, HAP, or other classification).

- The Mixtures database enables the user to create complete material compositions. Component vapor pressures are calculated using Raoult’s Law which can be further customized using Activity Coefficients.

- The Chemicals database is easy to use and contains many of the compounds that were featured in Tanks 4.09d software. New chemical records are easy to add to the database and a web link is provided for importing compounds directly from www.ChemSpider.com.

- Control devices including condensers, scrubbers, and thermal oxidizers may be specified in the vent path of each storage tank.

- Reports including a detail calculation report and other summary reports are exported to Excel.

- Fugitive emissions can be calculated for each storage tank based on component counts (SOCMI or field measured factors).

- Completed Emission Master Tanks calculation models may be imported into Emissions Accountant for use in facility wide emissions tracking and reporting purposes.

Storage Tank Calculation Workflow

Our streamlined workflow accommodates different needs and empowers fast and efficient storage tank emission modeling.

-

Initial Setup

- Install Emission Master Tanks software.

- Import storage tank equipment records from EPA Tanks 4.09d if needed.

- Many chemical records already present in the Chemicals database but new compounds are easily be added.

-

Storage Tank Emission Calculations

Storage Tank Calculations may be calculated for any daily, monthly, quarterly or yearly period.

-

-

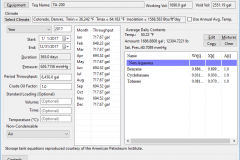

Create a storage tank model manually by selecting Storage Tank from below the Add Step main menu. After entering a title, select a storage tank to use, a climate location. Next, specify the material being stored and the period throughput. Finally, press the OK button to see the calculated results.

Create a storage tank model manually by selecting Storage Tank from below the Add Step main menu. After entering a title, select a storage tank to use, a climate location. Next, specify the material being stored and the period throughput. Finally, press the OK button to see the calculated results.  Alternatively, storage tank calculations may also be created directly from Excel. The spreadsheet can be populated from production data or other records using either mixture or compound names. Emission Master Tanks will import the data from Excel and automatically generate the storage tank calculations. In most cases, tank data can be taken from SAP or other material management systems.

Alternatively, storage tank calculations may also be created directly from Excel. The spreadsheet can be populated from production data or other records using either mixture or compound names. Emission Master Tanks will import the data from Excel and automatically generate the storage tank calculations. In most cases, tank data can be taken from SAP or other material management systems.

-

-

Reporting

- Emission results are itemized separately for breathing losses, working losses, total losses for the period and total losses on an hourly basis.

- Immediate calculation results are displayed in a table below the activity list. This data may be instantly copied or sent to Excel via a context menu.

- Emission Master Tanks supports generation of standard RTF text and Excel reports suitable for printing or inclusion in other documents.

- Classified Emissions (VOC, HAP, etc…) reports may also be generated for each tank in the study.

- If fugitive factors have been defined for storage tanks then a Fugitive Report may also be run. The fugitives are automatically calculated based upon the defined component leak rate factors and the tank contents.

- A detailed storage tank calculation report is included which shows the intermediary calculation values used to calculate the final emissions.

- To include storage tank emissions as part of a plant wide emissions inventory, use Emissions Accountant. Emissions Accountant is fully compatible with Emission Master Tanks and also includes advanced import tools to make Storage Tank and Fugitive calculations fully automated.

- Emission results are itemized separately for breathing losses, working losses, total losses for the period and total losses on an hourly basis.

Purchase an Emission Master Tanks license for as little as $525/year.